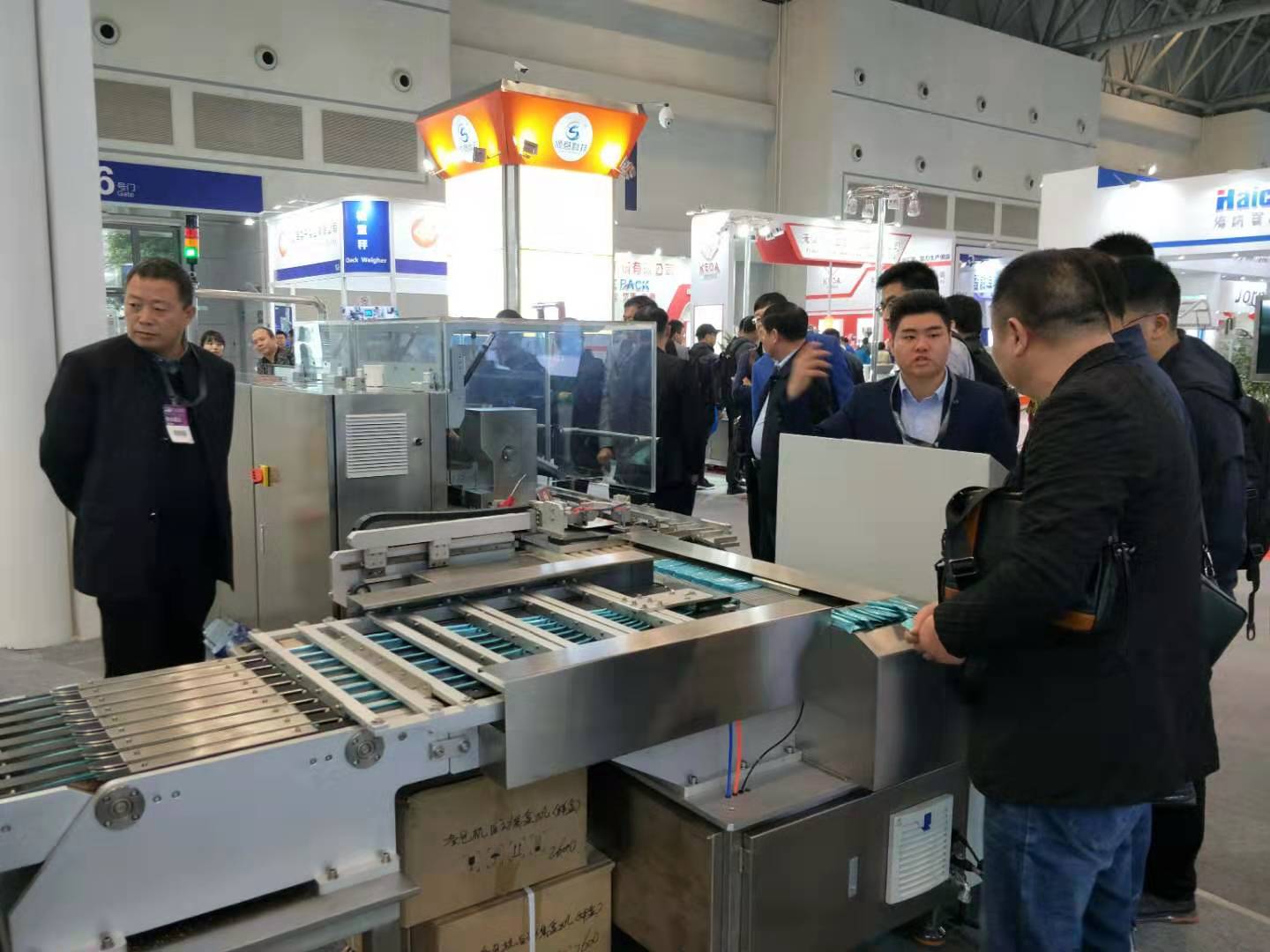

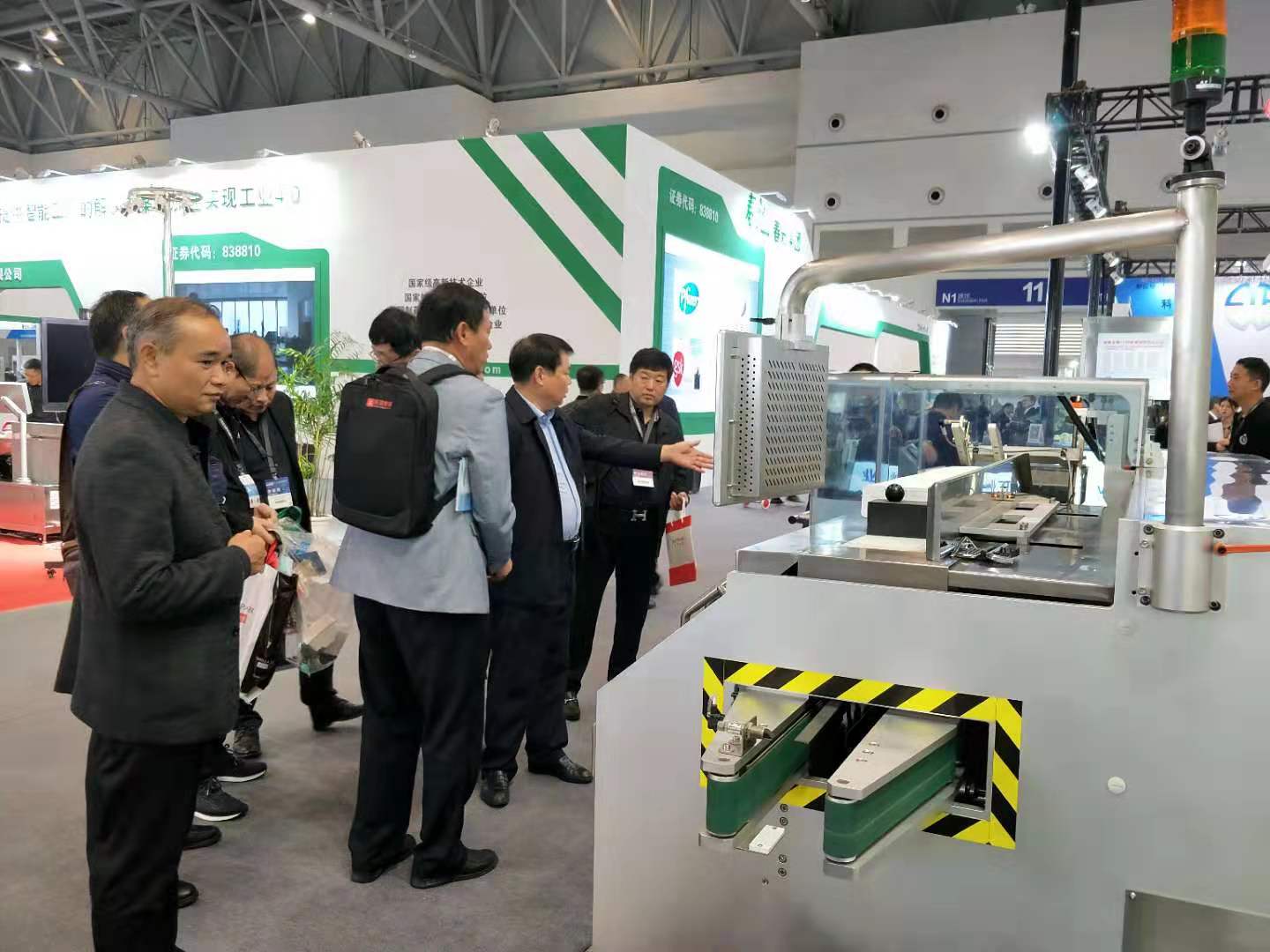

八台机器亮相58届重庆展会

江西万申于11月5日-7日参加在重庆举办的第58届全国制药机械博览会(CIPM)圆满落幕,展会以“创新、超越、发展”为主题,充分展示了万申企业的精神面貌与企业实力。在展会上,万申与来自全国各地,以及亚洲、欧美等地区的客户进行了洽谈和交流。

此次展会,万申为大家现场展示了8台机器的装盒过程,下面由小编依次为大家介绍这八台参展装盒机的性能与特点吧!

一、HDZ-150B 泡罩板自动装盒机

设备主要用于泡罩成形的胶囊、片剂、外包装铝箔包装的泡置板及类似规格物品的自动装盒。该机可单独操作。前端与枕式包装机连线生产效率更高。

The equipment is mainly used for automatic cartoning of blister formed capsules, tablets, blister plates with extemal aluminum foil packaging and other similar objects. This machine can be operated separately. Its front end can be connected with the pillow packaging machine to realize higher production efficiency

性能特点

变频调速,采用PLC全自动控制系统。

It adopts variable frequency speed control and PLC,automatic control system

采用人机界面操作系统,自动显示装盒速度、数量等性能参数,并显示故障原因和操作保养方法。

It adopts the human-machine interface operatingsystem, which automatically displays the cartoning speed, quantity and other performance parameters, and also displays fault causes and operation and maintenance methods

在同合设备规定范围内可实现多规格的调整使用。手动和自动转换功能。

The adjustment and use of various specifications within the stipulated range can be realized in one machine It is provided with manual and automatic switching functions.

同步完成说明书的折叠装盒功能。

The use instructions folding and cartoning functions can be completed synchronously.

在药盒上同步打印三排批号,并可加装打印流水号功能

Three rows of batch numbers can be printed on the medicine box synchronously, and the function of printing the serial number can be added.

设有自动检测系统,对不合格产品设有定位停机并在线剔除功能。

It is provided with the automatic detection system, and the fur nction of positioning, stopping and online elimination is provided for nonconforming products.

可配装热熔胶机。

It can be equipped with the hot melt adhesive machine.

|

型号Model |

HDZ-100B |

HDZ-150B |

|

纸盒规格Carton size(L*W*H) |

65-110*45-90*12-55mm |

|

|

装盒速度Speed |

60-100盒/分Box/min |

80-150盒/分Box/min |

|

主机尺寸Dimensions |

1150*1120*1550mm |

1350*1120*1650mm |

|

重量Weight |

850KG |

1000KG |

|

电压Voltage |

380V/50Hz |

|

|

功率Power |

1.1KW |

1.5KW |

|

压缩空气Compressed air |

0.6Mpa |

|

|

耗气量Air consumption |

30-90L/min |

50-150L/min |

|

说明书规格Specification |

110-160*90-250mm |

|

二、HDZ-150P 瓶型装盒机

主要用途

该设备主要用于瓶型(圆瓶、方瓶、扁瓶、异型瓶)物品的自动装盒,广泛适用于制药、日化、食品等行业类似产品的包装

The equipment is mainly used for automatic cartoning of bottle products(round bottles, square bottles, flat bottles irregular-shaped bottles). It is widely applied for packaging of similar products in such industries as medicine, daily chemical industry, food, etc

性能特点

◆变烦调速,采用PLC全自动控制系统。

It adopts variable frequency speed control and PLC automatic

control system

◆采用人机界面操作系统,自动显示装盒速度、数量等性能参数,并显示故障原因和操作保养方法。

It adopts the human-machine interface operating system, which automatically displays the cartoning speed, quantity and other performance parameters, and also displays fault causes and operation and maintenance methods

◆在同台设备规定范围内可实现多规格的调整使用。

The adjustment and use of various specifications within the stipulated range can be realized in one machine

◆手动和自动转换功能。

It is provided with manual and automatic switching functions

◆同步完成说明书的折叠装盒功能。

The use instructions folding and cartoning functions can be completed synchronously.

◆在药盒上同步打印三排批号,并可加装打印流水号功能

Three rows of batch numbers can be printed on the medicine

box synchronously, and the function of printing the serial number can be added

◆设有自动检测系统,对不合格产品设有定位停机并在线剔除功能。◆可配装热熔胶机

It is provided with the automatic detection system, and the function of positioning, stopping and online elimination is provided for nonconforming products.

◆自动整理储存药瓶,对接前端贴标机连线生产。

It can be equipped with the hot melt adhesive machine The medicine bottles are arranged and stored automatically and linked production can be realized through connection with the front-end labeling machine

◆具有自动分瓶入料防擦功能。

It is provided with automatic bottle distribution, feeding and

anti-rubbing functions

◆该机可与前后端设备连线生产

The machine can realize linked production through connection with front-end and rear-end equipment.

|

型号Model |

HDZ150P |

HDZ-100P |

|

纸盒规格Carton size(L*W*H) |

50-120*25-50*25-50-70mm |

|

|

装盒速度Speed |

80-150盒/分Box/min |

60-100盒/分Box/min |

|

主机尺寸Dimensions |

2400*1000*1650mm |

2300*1200*1550mm |

|

重量Weight |

1050KG |

850KG |

|

电压Voltage |

380V/50Hz |

|

|

功率Power |

1.5KW |

1.1KW |

|

压缩空气Compressed air |

0.6Mpa |

|

|

耗气量Air consumption |

30-90L/min |

|

三、HDZ-150BZ 枕包型自动装盒机

主要用途

该设备主要用于铝塑泡罩板枕包后(包括铝箔袋装泡罩板枕包后)及类似物品枕包后的自动装盒。

The equipment is mainly used for automatic cartoning after pillow packaging of aluminum-plastic blister plates (including pillow packaging of aluminum foil bag packaged blister plates) and similar objects.

性能特点

◆变频调速,采用PLC全自动控制系统

It adopts variable frequency speed control and PLC automatic control system

◆采用人机界面操作系统,自动显示装盒速度、数量等性能参数,并显示故障原因和操作保养方法。在同台设备规定范围内可实现多规格的调整使用。

It adopts the human-machine interface operating system, which automatically displays the cartoning speed, quantity and other performance parameters, and also displays fault causes and operation and maintenance methods

◆手动和自动转换功能。

The adjustment and use of various specifications within the stipulated range can be realized in one machine.

◆同步完成说明书的折叠装盒功能。

It is provided with manual and automatic switching functions. The use instructions folding and cartoning functions can be completed synchronously

◆在药盒上同步打印三排批号,并可加装打印流水号功能

Three rows of batch numbers can be printed on the medicine box synchronously, and the function of printing the serial number can be added

◆设有自动检测系统,对不合格产品设有定位停机并在线剔除功能。

It is provided with the automatic detection system, and the function of positioning, stopping and online elimination is provided for nonconforming products

◆可配装热熔胶机。

It can be equipped with the hot melt adhesive machine

◆手工加料,料仓直推或侧分直推,也可与枕包机连线气缸控制进同步带,再由同步带带入推料位置进盒。

Manual feeding, material Silo direct pushing or lateral distributiom and direct pushing. It can also be connected with the pillow packaging machine. The cylinder controls the synchronous belt and then the synchronous belt will drive the materials to the material pushing position for entering the carton

|

型号Model |

HDZ100BZ |

HDZ-150BZ |

|

纸盒规格Carton size(L*W*H) |

60-150*45-90*12-55mm |

|

|

装盒速度Speed |

60-100盒/分Box/min |

80-150盒/分Box/min |

|

主机尺寸Dimensions |

1500*1120*1550mm |

3750*1000*1650mm |

|

重量Weight |

850KG |

1050KG |

|

电压Voltage |

380V/50Hz |

|

|

功率Power |

1.1KW |

1.5KW |

|

压缩空气Compressed air |

0.6Mpa |

|

|

耗气量Air consumption |

30-90L/min |

|

四、HDZ-150K 水针型自动装盒机

主要用途

该设备主要用于针剂类在托盘内或泡罩好的针剂药品及类似规格物品的自动装盒,与前端印字入托设备或制托印字入托设备连线操作更能提高生产效率

The equipment is mainly used for automatic cartoning of injections in the tray or after blister packaging and other similar objects. After connection with the front-end printing and feeding equipment, or tray making, printing and feeding equipment, the production efficiency will be higher

性能特点

◆变频调速,采用PLC全自动控制系统。

It adopts variable frequency speed control and PLC automatic control system

◆采用人机界面操作系统,自动显示装盒速度、数量等性能参数,并显示故障原因和操作保养方法。

It adopts the human-machine interface operating syster Which automatically displays the cartoning speed, quantity and other performance parameters, and also displays fault causes and operation and maintenance methods

◆在同合设备规定范围内可实现多规格的调整使用。

The adiustment and use of various specifications within the stipulated range can be realized in one machine

◆手动和自动转換功能。

lt is provided with manual and automatic switching functions.

◆同步完成说明书的折叠装盒功能。

The use instructions folding and cartoning functions can be

completed synchronously

◆在药盒上同步打印三排批号,并可加装打印流水号功能。

Three rows of batch numbers can be printed on the

medicine box synchronously, and the function of printing the serial number can be added

◆设有自动检测系统,对不合格产品设有定位停机并在线剔除功能

lt is provided with the automatic detection system, and the function of positioning, stopping and online elimi nination Is provided for nonconforming products

◆可配装热熔胶机。

It can be equipped wit ith the hot melt adhesive machine

◆设有二次输送入盒功能,防打破针剂类产品。

It is provided with the twice conveying and cartoning function to avoid breaking injection product.

|

型号Model |

HDZ-100K |

HDZ-150K |

|

纸盒规格Carton size(L*W*H) |

110-160*70-90*12-35mm |

|

|

装盒速度Speed |

50-80盒/分Box/min |

80-150盒/分Box/min |

|

主机尺寸Dimensions |

3150*1120*1550mm |

3750*1120*1650mm |

|

重量Weight |

850KG |

1050KG |

|

电压Voltage |

380V/50Hz |

|

|

功率Power |

1.1KW |

1.5KW |

|

压缩空气Compressed air |

0.6Mpa |

|

|

耗气量Air consumption |

30-90L/min |

|

|

说明书规格Specification |

110-160*90-250mm |

110-160*90-250mm |

五、ICM12004-S全伺服智能自动装盒机

主要特点

◆全界面智能触控交互系统,智能参数设定,操作直观方便

full-interface intelligent touch interactive system, intelligent parameter setting, intuitive and convenient operation

◆整机采用开放式外观设计,便于监察机器运行状态和检修

The whole machine adopts open design, which is convenient for monitoring the running status and maintenance of the machine

◆由德国 Beckhoff全伺服驱动系统及控制系统,来完成复杂而精确的运动;

Beckhoff full servo drive system and control system from Germany to complete complex and precise movement

◆主要电器元器件均采用原装国际顶级品牌,性能稳定;

The main electrical components are all original international top brands with stable performance

◆各大系统模块化设计,独立可控;可重构式料仓,更换规格简单方便;

Modular design of each system, independent and controllable reconfigurable silo, easy to change specifications

◆采用同步带传动,传动平稳效率高,噪音低;

Adopt synchronous belt transmission, the transmission is smooth and efficient with low noise

◆可对条包进行叠层,实现多层装盒;

The sticks can be stacked to realize multi-layer boxing

◆双进双推装盒功能,设备低速运行,产能双倍增效。

Double-in and double-pushing cartoning function, the equipment

runs at low speed and doubles the production capacity

◆整机无需润滑,维护保养简单方便,同时也避免二次污染;

The whole machine does not need lubrication, the maintenance is

simple and convenient, and it also avoids secondary pollution

◆采用螺杆式调整参数精确数字显示,缩短更换规格时间;

Accurate digital display with screw adjustment parameters to shorten the replacement specification time

◆没备状态实时显示,自动计数、提示并记录故障信息;

Real-time display of device status, automatic counting, prompting and recording fault information

◆可存储多组包装产品参数,满足产品种类繁多时自动加载不同产品参数的需求;

It can store multiple sets of packaging product parameters, and meet the needs of automatically loading different product parameters when there are many kinds of products

◆人机界百符合数字签名要求,操作可按等级自由分配

The human-machine interface complies with the digital signature requirements, and the operation can be freely allocated according to the level.

◆可升降的纸盒料仓设计,平时低位,方便加料,检修时可升起方便检修;

Carton magazine designed to be lifted up and down, usually at low position for convenient refill and can be lifted up for easy maintenance

◆控制系统与外国设备全部采用工业以太网通信,响应快适应性强,符合用户工厂未来网络化建设需求。

The control system and peripheral equipment all adopt industrial

Ethernet communication, and the response is fast adaptable, which meets the needs of the future network construction of the user's

factory.

二、技术参数

|

型号Model |

ICM1204-S |

|

纸盒规格Carton size(L*W*H) |

70-160*25-105*15-70mm |

|

装盒速度Speed |

≦120Cartons/min |

|

主机尺寸Dimensions |

4220*1360*1560mm |

|

重量Weight |

2500KG |

|

电压Voltage |

380V/50Hz |

|

功率Power |

6KW |

|

压缩空气 Compressed air |

0.6Mpa |

|

耗气量Air consumption |

30-90L/min |

六、HDZ-300P 全伺服连续式高速装盒机

Continuous high speed cartoning machine

一、性能特点:

1、全界面智能触控交互系统,智能参数设定,操作直观方便;

Full-interface intelligent touch interactive system,intelligent parmeter setting, intutive and convenient operation;

2、整机采用开放式外观设计,便于监察机器运行状态和检修;

The whole machine adopts open design, which is convenient for monitoring the running status and maintenance of the machine;

3、采用全伺服驱动及运动控制系统来完成复杂而精确的运动;

Full servo drive and motion control system to complete complex and precise motion;

4、主要电器元器件均采用原装国际顶级品牌,性能稳定;

The main electrical components are all original international top brands with stable performance;

5、人机界面可显示装盒速度、数量、故障原因等生产信息,并内置了操作保养方法;

Human machine interface can display production information such as cartoning speed, quantity, and cause of failure, and built-in operation and maintenance methods;

6、在同台设备规定范围内可实现多规格的调整使用;

Multi-size products can be packed on the same equipment within specified scope;

7、采用人性化的机械记忆装置,通过表盘手轮调节能快速简单调换不同纸盒规格;

Using humanized mechanical memory device, quickly and easily make changeover for differen carton specifications through the dial handweel adjustment;

8、可手动自动转换功能;

Manual and automatic conversion fuction;

9、配置钢字打印机构,可在药盒上打印批号、生产日期和有效期等信息;

With device of embossing stamp, can make batch No. , production date and expiry date on box;

10、配置自动检测系统,对不合格产品可进行定位停机并在线剔除功能;

With auto detection system, can perform positioning stop and online rejecting for unqualified products;

11、可加装热熔胶机,实现点胶封盒功能;

It can be equipped with hot melt glue machine to relize the sealing by dotting adhesive;

12、可加装折纸机,同步完成说明书的折叠、输送、装盒功能。

It can be installed with folding machine to complete the folding, conveying and cartoning of leaflet.

二、技术参数:

|

型号Model |

HDZ-3OO |

|

纸盒规格Carton size(mm) |

L:80 W:20-90 H:15-55 |

|

装盒速度Speed |

≦300Cartons/min |

|

主机尺寸Dimensions |

4500*1280*1800mm |

|

重量Weight |

3200KG |

|

电压Voltage |

380V/50Hz |

|

功率Power |

3.7KW |

|

压缩空气Compressed air |

0.6Mpa |

|

耗气量Air consumption |

30-90L/min |

七、WS350 透明膜三维包装机

万申牌系列透明膜三维包装机是机电一体化的高科技产品,完全符合GMP标准要求。采用先进的PLC和伺服驱动控制技术,将输送带喂入的单个或多个小盒,用BOPP或PVC等透明膜进行包裹、折叠、成型、封盒等一系列工作程序完成三维包装。美化产品外观,并起到防潮、防伪作用,可替代中盒包装,降低成本。该机可与各类型装盒机组成装盒裹包生产线。广泛应用于药品、食品、保健的全封闭三维包装。

Wanshen brand series Cellophane overwrapping machine is a high-tech product of mechatronics, which fully meets GMP requirements. Using advanced PLC and servo drive control technology, the single or multiple small boxes fed by the conveyor belt are packaged, folded, formed, and sealed by BOPP or PVC to complete the packa aing. Improving the product appearance and getting the effects of moisture-proof and anti-counterfeiting, can replace medium box packaging to reduce the cost. It can be connnected with cartoning machine to form a cartoning and overwrapping production line. It is widely used in fully sealed three-dimensional packaging of medicines, foods and healthcare

|

型号Model |

WS-350 |

WS-550 |

|

纸盒规格Carton size(mm) |

L:50-280 W:40-140 H:10-100 L+H≦350 |

L:50-480 W:40-140 H:10-100 L+H≦550 |

|

装盒速度Speed |

≦40PCS/min |

≦30PCS/min |

|

主机尺寸Dimensions |

主机220*960*1760mm,输送台1500*220*880mm |

|

|

重量Weight |

750KG |

|

|

电压Voltage |

380V/50Hz |

|

|

功率Power |

3.75KW |

|

|

压缩空气Compressed air |

0.6Mpa |

|

|

耗气量Air consumption |

≧210L/min |

|

八、HDZ-220连续式高速装盒机

主要特点

◆采用变频调速,PLC全自动控制系统。

Adopt variable frequency speed regulation, PLC automaticcontrol system

◆人机界面可显示装盒速度、数量、故障原因等生产信息,并内置了操作保养方法;

Human machine interface can display production information such as cartoning speed, quantity, and cause of failure, andbuilt-in operation and maintenance methods

◆在同台设备规定范围内可实现多规格的调整使用

multi-size products can be packed on the same equipmentwithin specified scope

◆采用人性化的机械记忆装置,通过表盘手轮调节能快速简单调换不同纸盒规格;

Using humanized mechanical memory device, quickly and easily make changeover for different carton specifications through the dial handwheel adjustment

◆可手动和自动转換功能;

Manual and automatic conversion function

◆配置钢字打印机构,可在药盒上打印批号、生产日期和有效期等信息;

With device of embossing stamp, can make batch Noproduction date and expiry date on box

◆配置自动检测系统,对不合格产品可进行定位停机并在线别除功能;

With auto detection system, can perform positioning stop and online rejecting for unqualified products

◆可加装热熔胶机,实现点胶封盒功能;

It can be equipped with hot melt glue machine to realize the sealing by dotting adhesive

◆可加装折纸机,同步完成说明书的折叠、输送、装盒功能。

It can be installed with folding machine to complete the folding.conveying and cartoning of leaflet

|

型号Model |

HDZ-220 |

HDZ-2204 |

HDZ-2205 |

|

纸盒规格Carton size(mm) |

L:58-200 W:20-70 H:14-70 |

L:58-200 W:20-120 H:14-70 |

L:58-200 W:20-150 H:14-17 W+H≦190 |

|

装盒速度Speed |

≦220Cartons/min |

≦150Cartons/min |

≦110Cartons/min |

|

主机尺寸Dimensions |

4100*1680*1800mm |

||

|

重量Weight |

3000KG |

||

|

电压Voltage |

380V/50Hz |

||

|

功率Power |

2.1KW |

||

|

压缩空气Compressed air |

0.6Mpa |

||

|

耗气量Air consumption |

30-90L/min |

||

万申印务展示样品

推荐产品

同类文章排行

- 喜讯!热烈祝贺我公司获得“高新技术企业”认证

- 【万申包装】邀您参观2020世界医药包装中国展

- 山东鲁抗舍里乐药业订购的HDZ-120已发货

- 石药集团订购的HDZ-120多功能装盒机已发货

- 江西万申正式开工

- 万申企业股东大会

- 向优秀人学习,不忘初心,不负韶华!

- 不忘初心 牢记使命|武功山游学活动

- 八台机器亮相58届重庆展会

- 万申秋游团建活动

最新资讯文章

- 装盒机的质量设计要求

- 药品对于装盒机的需求

- 自动装盒机在很多场合上受客户的青睐

- 三维包装机的基本常识

- 自动装盒机的使用优势与特点

- 泡罩机需要注意的事项有什么呢?

- 装盒机的工作流程是怎样

- 装盒机的质量问题

- 自动装盒机一般都有哪些什么小故障呢?

- 自动装盒在国内发展迅速

您的浏览历史